Tianjin Yixin Pipe Equipment Co., Ltd. specializes in the production of various types of closed type orbital welding machine, automatic pipe welding equipment, automatic pipe and pipe welding machines, all-position automatic welding machines, all-position pipe and pipe welding machines, closed type pipe and pipe welding machines, automatic tube and tube welding machine, automatic tube and tube argon arc welding machine, portable automatic argon arc welding machine, automatic argon arc welding machine, etc., is a professional orbital automatic welding machine welding machine manufacturer. The automatic welding equipment produced by Tianjin Yixin is used all over the world. I'd like to introduce the principle and characteristics of the closed type pipe automatic welding machine briefly.

1. Working principle of pipe welding equipment

l The closed tube tube welding system is composed of a welding power source and a welding torch. The equipment is exquisite and can be used for various field and workshop operations.

l The system adopts PLC control, and develops a special pipe and pipe welding control system. The customer only needs to input the pipe diameter and wall thickness of the weldment, and the control system can run automatically. Start the gas protection and water cooling protection → start the welding machine → start the rotating motor → follow the setting. Welding at a fixed rotation angle → automatic finishing welding → delayed shutdown of water cooling and gas protection → welding is completed, the welding seam is beautiful, and can meet various flaw detection requirements.

2. Advantages of pipe welding equipment

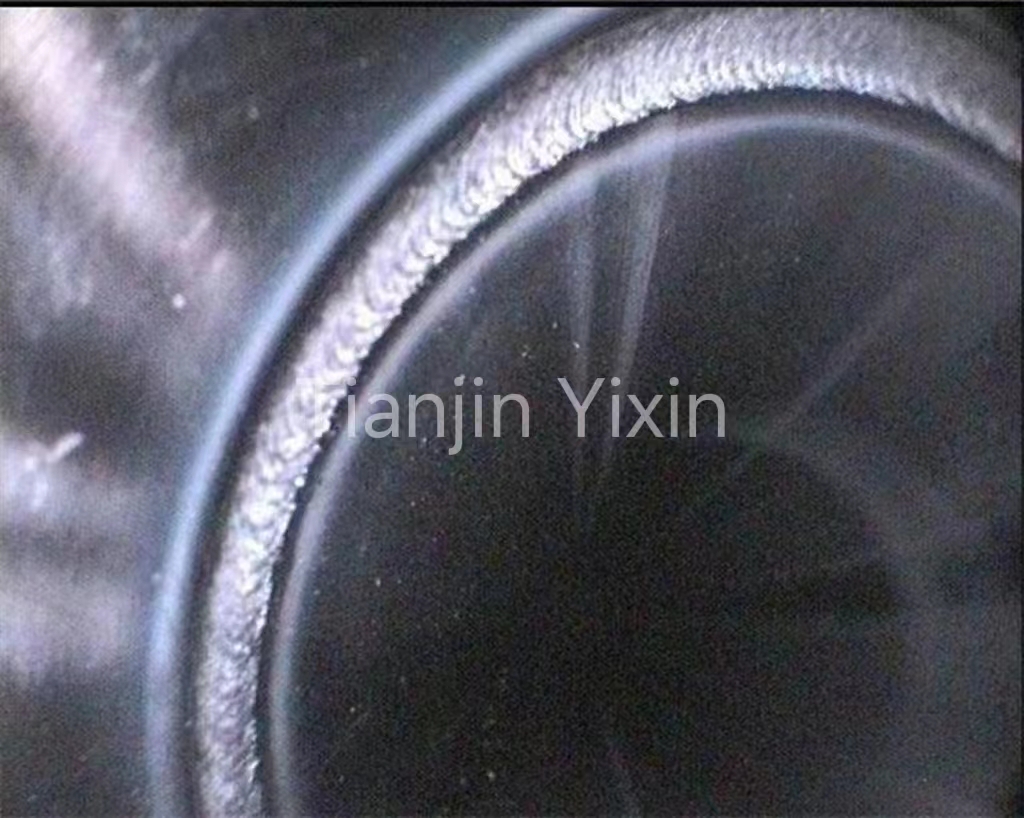

- The equipment adopts the tungsten argon arc welding process, and with the torch water cooling system, it can realize single-sided welding and double-sided forming, and easily realize all-position welding;

- The appearance of the welding seam is uniform and beautiful;

- Welds can be tested for flaw detection.

- The intelligent digital automatic welding control system can automatically call the relevant data of the expert database for automatic welding;

- Equipped with expert database, welding is convenient and intelligent;

- The welded products meet the welding requirements of stainless steel clean pipelines;

- The equipment adopts imported core components, which are precise, efficient and durable, and can be used for efficient welding in various working conditions.

Post time: Oct-27-2022